Drop Deck Trailers

MORE PAYLOAD

When margins are slim, you must look for ways to maximize payload to increase your profitability. So, East designs one of the lightest and strongest aluminum drop deck trailers on the road today.

MORE STRENGTH

The main beams and the structural cross members use 6061-T6 aluminum, offering all the durability of high-tensile-strength steel at a reduced weight.

MORE VERSATILITY

For more profitability, the combination of lightweight, strength and high load ratings gives you versatile and flexible load options.

HIGHER RESALE VALUE

East trailers have a reputation for quality that brings a higher resale value. Many East drop decks remain on the highway over 30 years still providing reliable service no other manufacturer can match.

Drop Deck Trailers

Setting the standard for long life and low maintenance, East drop deck trailers are one of the lightest and strongest on the market, available in overall lengths up to 53 feet. To keep weight down, East drop deck trailers feature the industry’s only true all-aluminum, one-piece neck; no bolts or steel reinforcement needed for today’s special load requirements.

Trailer Strength

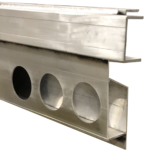

The strength of our drop deck trailers is our double T-shape extruded main beam and exclusive tubular cross-member design, increasing durability and balancing load stresses more evenly for longer life and less maintenance. Its two T-shape extrusion sections of 6061-T6 aluminum alloy are welded, not bolted. The weld is in the neutral axis where stress is minimal. Our 2″ x 5″ tubular cross members are more twist resistant in a turn than conventional C-channel and I-beam cross members.

Extra Strong Neck Design

Our exclusive one-piece all-aluminum, double-contour neck design drastically reduces stress in the transition area for greater strength and longer life with a lower overall trailer weight.

Beast (BST Drop)

Offering a structural load rating of 80,000 lbs. distributed, it can carry up to 2,500 lbs. more payload than a comparable steel drop deck, and up to 1,200 lbs. more than a comparable composite.

Beast II (BST II Drop)

Designed with all the features and benefits of the BST, the BST II DROP meets the needs of applications requiring higher load ratings without additional weight. It is rated up to 100,000 lbs. distributed with a tandem axle. And, it boasts a 2-inch deeper main beam than the BST DROP.

Extreme Low Deck (XLD)

Designed for increased payload versatility and better stability, the first all-aluminum drop deck trailer with a low-slung 36-inch deck height offers a lower center of gravity. With specialty loads, particularly equipment loads getting taller and taller, the new low-height East drop deck reduces the need for partial dismantling of the load to get it below the 13-feet 6-inch maximum legal height. Available in Beast and Beast II.

Standard Features

The fully-enclosed floor design with full-length continuous welds joining the floor decking to the main-frame beams provides maximum strength and resistance.

The fully-enclosed floor design with full-length continuous welds joining the floor decking to the main-frame beams provides maximum strength and resistance.

Fully-sealed rear panel is water resistant. Recessed grooves protect conspicuity tape and rubber dock blocks, and a heavy-wall bumper provides added protection.

Fully-sealed rear panel is water resistant. Recessed grooves protect conspicuity tape and rubber dock blocks, and a heavy-wall bumper provides added protection.

Hollow-core siderail design provides a conduit for wiring to be fully enclosed. Standard with LED PC-rated grommet-mounted lights.

Hollow-core siderail design provides a conduit for wiring to be fully enclosed. Standard with LED PC-rated grommet-mounted lights.

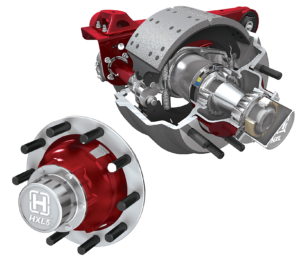

The READY-TO-ROLL HXL5® is designed to maximize uptime and efficiency and reduce wheel-end maintenance. The preassembled and adjusted HXL5 features a premium seal, high-performance synthetic semi-fluid grease and a PRECISION320™ spindle nut system, which allows for ultra-precise bearing adjustment.

Up to 50 pounds lighter per set and no external gearbox, the AX150 Alumilight includes a galvanized inner lower leg, crank handle and cross shaft. With a 160,000-lb static rating and a 55,000-lb lift, the maintenance free landing gear comes standard with a 10-Year Warranty.

Up to 50 pounds lighter per set and no external gearbox, the AX150 Alumilight includes a galvanized inner lower leg, crank handle and cross shaft. With a 160,000-lb static rating and a 55,000-lb lift, the maintenance free landing gear comes standard with a 10-Year Warranty.

To guard against corrosion, the harness has been designed as a closed system by integrating a model plug with two sealing surfaces rather than just one.

To guard against corrosion, the harness has been designed as a closed system by integrating a model plug with two sealing surfaces rather than just one.

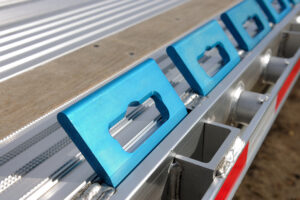

Sidereal extrusions are designed for adjustable chain tie-downs and a unique winch strap capture system.

Sidereal extrusions are designed for adjustable chain tie-downs and a unique winch strap capture system.

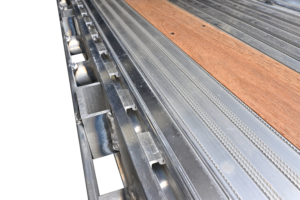

The new integrated extruded aluminum outside rail tie down system for cargo securement is standard on all East flatbed and drop deck trailers, eliminating the need for welds and reducing assembly time. Available as an option on the inside and center tie down tracks.

The new integrated extruded aluminum outside rail tie down system for cargo securement is standard on all East flatbed and drop deck trailers, eliminating the need for welds and reducing assembly time. Available as an option on the inside and center tie down tracks.

Ultra ONE® 22.5″ x 8.25″ aluminum wheel is standard. At just 39 pounds, the wheel is the lightest wheel in its class and strong enough for demanding applications.

Ultra ONE® 22.5″ x 8.25″ aluminum wheel is standard. At just 39 pounds, the wheel is the lightest wheel in its class and strong enough for demanding applications.

Optional Features

The only truly “heavy duty” aluminum toolboxes on the market built with 3/16-inch aluminum and fully (not stitch) welded for extra strength and durability.

The only truly “heavy duty” aluminum toolboxes on the market built with 3/16-inch aluminum and fully (not stitch) welded for extra strength and durability.

Aluminum built-in tarp storage compartment can be built into the floor of the upper or lower deck. This on-deck access location reduces multiple ups and downs on the trailer (lessening the chance for falls) to tarp the load, or store the tarp and tie-downs, saving time and energy. Available in various depth configurations.

Aluminum built-in tarp storage compartment can be built into the floor of the upper or lower deck. This on-deck access location reduces multiple ups and downs on the trailer (lessening the chance for falls) to tarp the load, or store the tarp and tie-downs, saving time and energy. Available in various depth configurations.

To eliminate welding and reduce assembly time, the optional inside and center tie down tracks are an extruded insert.

To eliminate welding and reduce assembly time, the optional inside and center tie down tracks are an extruded insert.

Integrated extruded aluminum siderail system to accommodate a Double-L winch with flat-hook straps for cargo securement.

Integrated extruded aluminum siderail system to accommodate a Double-L winch with flat-hook straps for cargo securement.